Shop Smart: Searching For Genuine OEM Construction Parts

Shop Smart: Searching For Genuine OEM Construction Parts

Blog Article

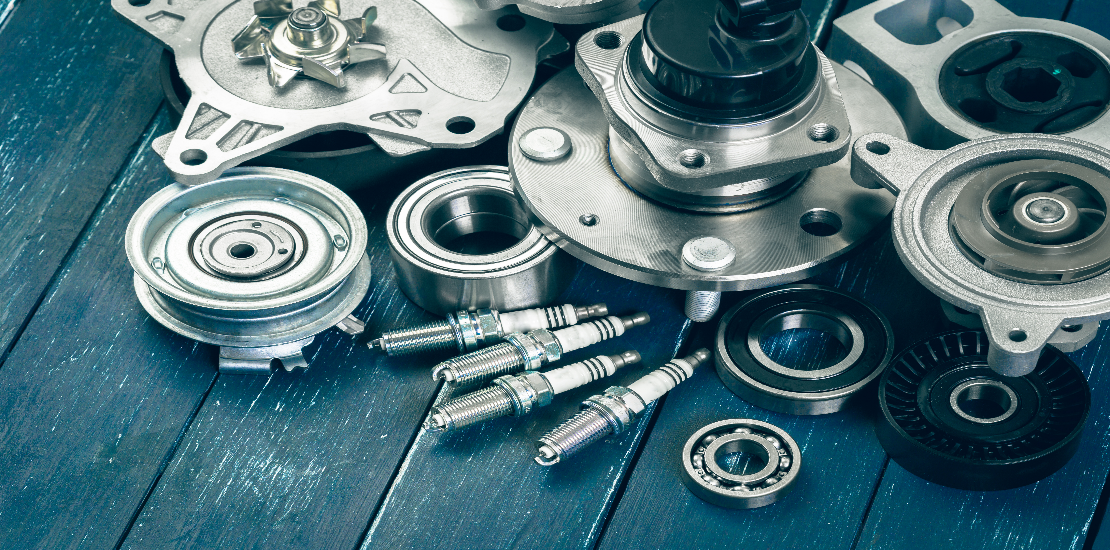

Trick Aspects to Think About When Picking OEM Building Parts for Optimum Performance

When striving for ideal performance in building equipment, the option of Original Equipment Supplier (OEM) parts plays a crucial function. The efficiency and long life of heavy equipment largely depend upon the components utilized for repair and maintenance. From making sure compatibility with specific devices versions to prioritizing top quality standards and dependability, each choice can impact the total functional success. In the competitive landscape of building and construction, where downtime translates to considerable economic losses, the careful consideration of vital factors when choosing OEM building and construction parts ends up being extremely important.

Compatibility With Equipment

When selecting OEM construction parts, guaranteeing compatibility with the certain tools is extremely important for optimum efficiency. Oem Construction Parts. Making use of components that are especially designed for the equipment concerned can significantly impact its functionality, longevity, and overall efficiency. Compatibility makes certain that the components fit flawlessly right into the existing system, lowering the threat of breakdowns and failures

Makers create OEM parts to accurate specifications that align with the tools they are planned for. These components go through rigorous screening to assure their compatibility and performance within the assigned machinery. Making use of non-OEM components can jeopardize this compatibility, resulting in inefficiencies, safety and security dangers, and prospective damage to the tools.

High Quality and Integrity Requirements

To ensure optimal performance and longevity of construction equipment, adherence to strict high quality and dependability requirements in choosing OEM parts is necessary. Quality criteria incorporate the products made use of, producing procedures, and general sturdiness of the parts. OEM parts that meet top quality standards are more probable to withstand the requiring problems of building sites, reducing the threat of failures and making certain smooth procedures. Reputable OEM parts are designed and examined to fulfill certain performance standards, guaranteeing they work perfectly with the tools they are intended for. By choosing OEM components that abide by stringent quality and reliability standards, building firms can reduce downtime, lower maintenance prices, and improve total efficiency. Additionally, reliable OEM manufacturers usually supply warranties on their components, even more guaranteeing their high quality and reliability. Focusing on quality and dependability in OEM construction components selection is a calculated investment that settles in terms of devices efficiency and operational performance.

Warranty and Assistance Choices

When choosing OEM building and construction components, it is important to take into consideration the warranty terms supplied by the manufacturer. A robust warranty can give tranquility of mind, ensuring that any possible issues with the parts will be resolved immediately and at very little price to the customer.

Along with guarantee insurance coverage, the degree of support offered by the OEM maker is just as important. Choose producers that use reliable customer support services, including technical support, fixing support, and prompt feedbacks to questions. A receptive assistance group can aid minimize equipment downtime and ensure that any issues are dealt with efficiently, helping you maintain optimal performance levels on the construction website. By meticulously reviewing the service warranty and assistance alternatives used by OEM makers, you can make educated decisions that add to the lasting success of your construction projects.

Cost-Effectiveness and Worth

Considering the overall cost-effectiveness and value of OEM building and construction components is important for making notified purchase choices in the construction industry. While in advance expenses are a substantial consideration, it is essential to look beyond the preliminary rate tag and assess the total expense of ownership over the component's life expectancy. Selecting high-quality OEM parts may need a higher preliminary investment however can lead to long-lasting cost savings by lowering the regularity of substitutes and decreasing downtime.

In addition, the worth of OEM building and construction components exists not just in their efficiency however likewise in the assurance of compatibility and dependability they provide. By selecting OEM parts from trusted producers, building companies can mitigate the risks related to making use of substandard or phony parts, inevitably securing their devices and guaranteeing optimal efficiency.

In reviewing cost-effectiveness and worth, construction professionals need to additionally think about elements such as warranty insurance coverage, technological support, and the schedule of authentic replacement components. While expense is an important factor, focusing on value and quality can bring about higher efficiency, performance, and overall financial savings over time.

Availability and Lead Times

The timely accessibility of OEM building and construction components is essential for making sure nonstop operations and project timelines in the helpful site building market. When choosing OEM components, one have to consider the supplier's ability to offer the needed parts without delay.

To ensure optimum performance and performance, building companies need to establish clear communication networks with OEM part vendors concerning preparations and accessibility. By proactively monitoring supply levels and projecting future part demands, firms can lessen the risk of unanticipated shortages. In addition, having a contingency strategy in position for unanticipated hold-ups can assist minimize the effect of supply chain disturbances on check my blog project routines.

Conclusion

Finally, picking OEM construction components requires mindful consideration of aspects such as compatibility with dependability, devices and top quality criteria, warranty and support choices, cost-effectiveness and worth, along with schedule and lead times - Oem Construction Parts. By prioritizing these essential aspects, organizations can ensure optimal performance and effectiveness in their building and construction tasks

When making every effort for optimal performance in construction equipment, the selection of Original Devices Producer (OEM) parts plays a vital duty. In the affordable landscape of building and construction, where downtime converts to substantial economic losses, the mindful factor to consider of vital variables when picking OEM building and construction components comes to be vital.

To make sure ideal performance and durability of building equipment, adherence to stringent quality and integrity criteria in picking OEM parts is crucial.Thinking about the general cost-effectiveness and value of OEM building and construction components is necessary for making notified procurement choices in visit their website the building and construction market.The timely schedule of OEM building and construction components is essential for ensuring uninterrupted procedures and job timelines in the construction sector.

Report this page